Unlocking the Full Potential of LFP Batteries: Advanced Nano-Wet Processing Technology for High-Performance Lithium Iron Phosphate Cathode Materials

As the world transitions to electric vehicles, renewable energy, and sustainable power systems, the demand for high-performance, cost-effective, and environmentally friendly battery materials has never been greater. Lithium Iron Phosphate (LFP) is rapidly gaining ground as one of the most sought-after cathode materials in the lithium-ion battery market.

Renowned for its exceptional thermal stability, non-toxic composition, and long cycle life, LFP has already made a significant mark in the sectors of electric mobility, grid storage, and portable electronics. However, its relatively low conductivity and energy density have historically posed performance challenges.

To address these limitations, scientists and manufacturers are turning to Nano-Wet Processing Technology, a groundbreaking approach that enhances the physical and electrochemical properties of LFP at the microscopic level.

Despite its advantages, LFP is inherently limited by its structure and material characteristics. These limitations include:

Low Electrical Conductivity: This results in slower charge and discharge rates compared to other cathode materials.

Limited Lithium-Ion Diffusion: The 1D lithium-ion channels within the olivine crystal structure restrict fast ion movement.

Lower Energy Density: With a voltage plateau around 3.2V, LFP cannot deliver as much energy per unit weight as other materials like NMC (Nickel Manganese Cobalt).

Overcoming these limitations is essential for optimizing battery performance, particularly in applications requiring fast charging, high power density, and consistent long-term operation.

Nano-wet processing is a highly engineered method of producing LFP cathode materials using nano-scale wet grinding and precision control over particle size distribution, chemical homogeneity, and surface area.

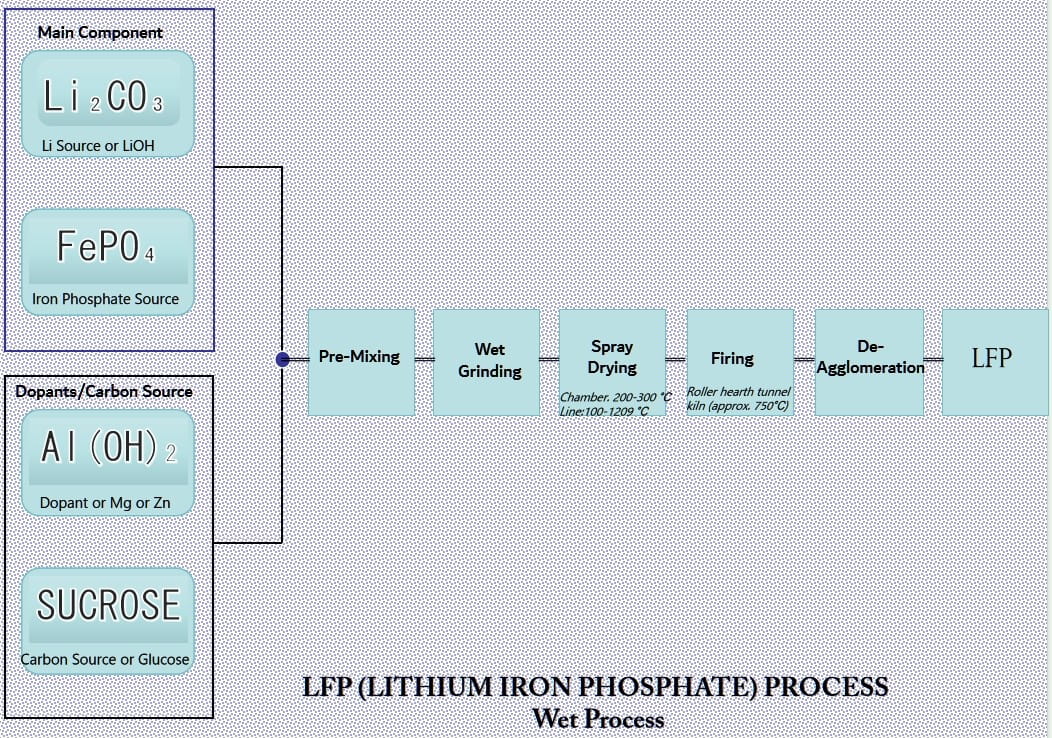

This method involves a series of tightly integrated steps that together deliver superior performance, including:

Pre-mixing of Raw Materials

Nano-Wet Grinding Using Bead Mills

Spray Drying to Form Precursor Powders

Controlled Sintering to Achieve Crystallization

Post-Processing Deagglomeration for Final Consistency

Each step is meticulously optimized to ensure maximum efficiency, product uniformity, and electrochemical capability.

The process begins with the precise blending of active and additive components, including:

Lithium carbonate (Li₂CO₃)

Iron phosphate or its derivatives (FePO₄ or RePO₄)

Aluminum hydroxide (Al(OH)₃) for doping

Sucrose or other carbon sources

These ingredients must be uniformly distributed before grinding to avoid compositional segregation during further processing. High-shear mixers or dispersers are typically employed to achieve an initial homogenous slurry.

This is the heart of the technology. The wet grinding process uses zirconia microbeads, typically 0.1–0.3 mm or 0.3–0.5 mm in diameter, to mechanically reduce particle size down to the nano or submicron level.

Rotational Speed: 2000–2500 rpm

Linear Tip Speed: 8–10 m/s

Grinding Duration: 45 to 90 minutes

Media Filling Rate: 60%–75%

Solid Content of Slurry: 45%–55%

Viscosity: Maintained at 3000–5000 cP

This stage ensures that the LFP precursor achieves a D50 (median particle size) of ≤1 μm, which is critical for enhancing ionic conductivity and charge transport.

Reducing the size of LFP particles leads to a significantly higher surface-to-volume ratio, which:

Enhances Li⁺ diffusion within the electrode

Improves electron pathways when carbon-coated

Minimizes diffusion distances for both ions and electrons

Facilitates better electrolyte penetration

When particles are shrunk to the nano-scale, they exhibit more uniform electrochemical behavior, providing consistent performance across the cathode material.

The use of zirconia grinding media offers several technical advantages:

High Density: Efficient energy transfer during grinding

Low Contamination: Chemically stable in acidic and basic environments (pH 2–12)

Mechanical Strength: Resistant to wear and fracture

Thermal Resistance: Ideal for high-speed operation

By ensuring clean and efficient grinding, zirconia beads preserve the chemical purity of the LFP slurry—critical for battery-grade materials.

Once grinding is complete, the slurry is transformed into a dry precursor powder using a spray dryer. This technique allows for:

Rapid moisture removal

Uniform particle sphericity

Controlled size distribution

Prevention of agglomeration

The resulting powders typically exhibit a D10/D90 particle size ratio of approximately 1.5, indicating tight control over particle uniformity.

The spray-dried precursor is then subjected to a sintering process at elevated temperatures (typically 650°C–750°C). This thermal treatment enables the formation of the olivine crystal structure characteristic of high-quality LFP.

During sintering:

Carbon additives decompose into a conductive coating

Mg and Al dopants integrate into the crystal lattice

Grain boundaries are defined for better ionic conduction

Sintering also enhances the mechanical and thermal stability of the final cathode material.

After sintering, the material may undergo post-processing steps to break down soft agglomerates and refine particle dispersion. This ensures:

Consistent powder flow

Uniform packing in electrode fabrication

Maximized active surface area

The final product typically achieves a tap density of ≥1.2 g/cm³, a key metric for volumetric energy density.

Because LFP lacks high intrinsic electrical conductivity, a carbon coating is essential to improve its performance in real-world batteries.

In nano-wet processing:

Sucrose is added during mixing and grinding

During sintering, it decomposes into amorphous carbon

This carbon forms a uniform conductive network around the nano-particles

The result is a material with enhanced electron transport, allowing for faster charge and discharge cycles.

Conventional LFP production methods rely heavily on dry mixing, which often leads to:

Inconsistent particle size

Poor dopant dispersion

Agglomeration and clustering

Uneven carbon coating

In contrast, nano-wet processing offers:

Superior homogeneity

Nano-level particle engineering

Efficient use of raw materials

Scalable and environmentally friendly production

These advantages contribute to a more robust battery performance profile, particularly under demanding conditions such as fast charging and high-rate discharge.

| Parameter | Typical Value |

|---|---|

| Median Particle Size (D50) | ≤1 μm |

| Specific Surface Area | 15–20 m²/g |

| Tap Density | ≥1.2 g/cm³ |

| D10/D90 Ratio | ≈ 1.5 |

| Sintering Temperature | 650–750°C |

| Slurry Solid Content | 45–55% |

| Slurry Viscosity | 3000–5000 cP |

These figures reflect a material that is optimized for high power, long cycle life, and stable thermal behavior—crucial traits for electric vehicles and grid-scale energy storage.

In addition to performance enhancements, nano-wet processing contributes to sustainability goals by:

Minimizing material waste

Operating in closed-loop systems for slurry handling

Lowering energy consumption via efficient sintering

Reducing airborne contaminants compared to dry powder handling

This makes the process both economically viable and environmentally responsible, aligning with the global push toward green manufacturing.

LFP cathode materials manufactured using this advanced technique are ideally suited for:

Electric Vehicles (EVs): Enhanced safety and longevity

Hybrid Electric Vehicles (HEVs): High discharge capability

Energy Storage Systems (ESS): Stable long-term performance

Consumer Electronics: Lightweight and fast-charging

Backup Power Systems: Reliable under variable load conditions

The versatility of nano-wet processed LFP makes it a cornerstone of next-generation lithium-ion battery technology.

As global demand for lithium-ion batteries accelerates, manufacturers are under pressure to scale production while maintaining consistent quality. Nano-wet processing is inherently adaptable to industrial-scale operations through:

Modular sand mill systems

Automated slurry handling

In-line particle size monitoring

Integrated spray drying and sintering units

Investing in this technology today will enable next-gen battery developers to meet future demands for high power, safe, and sustainable energy solutions.

Nano-Wet Processing Technology represents a significant leap forward in the development of LFP cathode materials. By overcoming the intrinsic limitations of LFP—such as low conductivity and limited rate capability—this method delivers a performance-optimized, scalable, and sustainable solution for the modern energy landscape.

With tighter control over particle size, dopant distribution, and carbon coating, nano-wet processed LFP stands out as the ideal choice for applications demanding safety, efficiency, and longevity.

Interested in adopting nano-wet processing for your battery materials?

Reach out to our technical support team to explore custom solutions, pilot-scale systems, and full-scale production line integration. Let us help you shape the future of energy storage—one nanoparticle at a time.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder